Tank Overfill Protection

Banlaw FillSafetm

Setting The Bar High For Zero Tank-Pressure Overfill Protection

Banlaw’s Tank Overfill Protection Systems help construction, mining, and rail operations that need to fill storage tanks and refuel diesel-powered machines. FillSafe, helps avoid equipment damage and maintenance costs from inaccurate filling, while increasing fuelling efficiency and site safety.

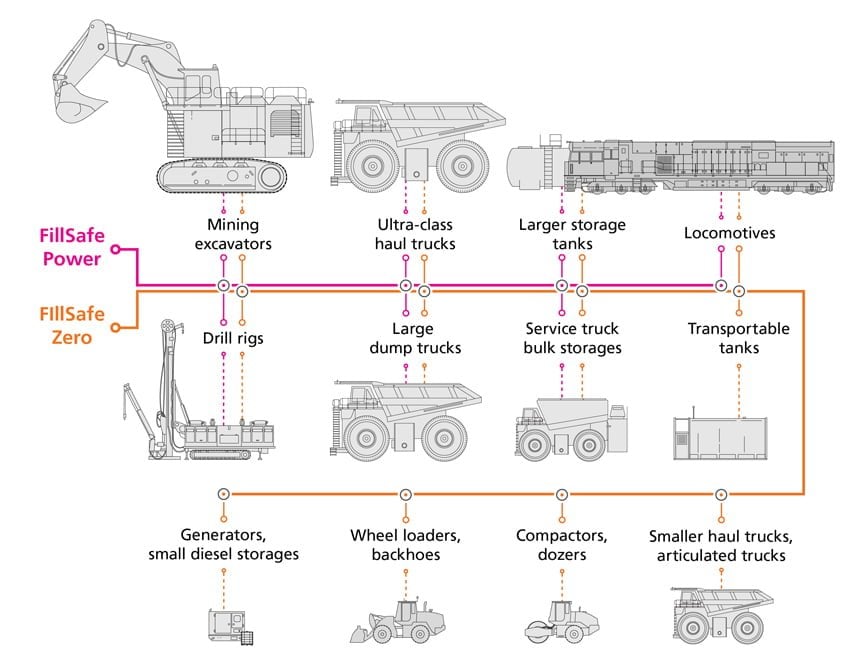

Banlaw has two overfill prevention product families, FillSafe Zero and FillSafe Power share the following key benefits:

- Reliable tank overfill protection – no wasted liquid (e.g. fuel) – no underfills – no guessing or checking if the tank is filled to capacity.

- Efficient design with superior flow characteristics – no premature shut-off when using ‘auto shut-off’ Dry Break nozzles – increased refuelling flow rates.

- No pressure build-up in the tank – avoids tank rupture and fatigue.

- Secondary (backup) overfill protection system – FillSafe Power and FillSafe Zero have a ‘pressurised tank’ backup shut-off system when deployed with Banlaw (or similar) Dry Break refuelling nozzles, receivers and vents.

Banlaw’s zero tank pressure overfill protection systems come in several configurations. This offers highly flexible deployment options, and addresses all common industrial use-cases:

- All mining and construction diesel-powered machines.

- Freight and passenger diesel locomotives.

- Small to medium fixed, transportable, and mobile fluid storages.

- Systems to control modest flow rates all the way up to thousands of gallons per minute.

FillSafe Power And FillSafe Zero

Banlaw FillSafetm Power Benefits:

- Totally unrestricted by flow rate.

- Diesel, DEF/AdBlue and many other fluids supported.

- FillSafe actuated valve maintained in normally closed (N/C) position for additional safety.

- Fire safe (e.g. API 607) compliant ball valves can be included for added fuel security during a fire.

- Not susceptible to fluid cleanliness issues.

- Multiple pre-set fill levels on the same machine.

- Can provide exact tank level feedback.

- Integrated visual cues and advanced safety features.

- Banlaw can provide a SIL-rated safety system on request

Learn more about FIllSafe Power or download product information

Banlaw FillSafetm Zero Benefits:

- ‘Hydraulically’ (fuel pressure)-powered design – no external power source or wiring.

- Simple install – no specialist skills required.

- 200lpm (53gpm) to 1000lpm (264gpm) flow rates supported.

- 2”, 3″, 4”, flanged, and threaded deployment options.

- Flow Control Valves available to fit within a standard shell (recessed tank fill point).

- Venting Level Sensors for tanks with only one process port connection for venting.

- Anti-spill ‘rollover protection’ integrated into the Level Sensor.

- Affordable diesel refuelling overfill protection kits for many machine types.

Learn more about FIllSafe Zero or download product information

Choosing The Right Tank Overfill Protection System For Your Application

Engineered Tank Overfill Protection Solutions

If you require a tank overfill protection system for a fuel farm or large fluid storage facility, then Banlaw can provide appropriate overfill prevention, plus alarms, electronic notifications, and SIL-rated safety systems as part of a Banlaw Fuel Management System.

Banlaw’s tank overfill protection systems give you full confidence every time you refuel or refill. The electronic and mechanical options within the Banlaw FillSafeTM family include the very latest technology, giving you overfill protection with absolutely no pressure build up in the tank.

Even at the highest refilling rates FillSafe delivers consistently accurate filling of tanks and storages to your specified levels – no underfilling or overfilling.

This product family is also available in Arctic Range variants.

Contact Banlaw today for a tank overfill protection system which will improve the productivity of your fleet. Fast Fills. No Spills.

Popular Content

Prevent fires on mine sites! Take ownership of maintenance

Due to a series of recent fires on mine sites, we’ve decided to focus this article specifically on the fire risk associated with using fuels and oils in an industrial setting. Banlaw team members spend well over 100,000 hours a year designing, building and maintaining dry break fuel systems, processes,...