FillSafe Zero – Mechanical Tank Overfill Protection System

Banlaw FillSafeTM Zero Safe, Fast, Reliable Filling

Banlaw’s mechanical tank overfill protection systems help mining, construction, and rail companies that need to refuel diesel-powered machines efficiently and safely.

They achieve this by avoiding productivity loss from underfills, overfills, and tank damage while delivering substantially higher flow rates under normal operating conditions.

Banlaw FillSafeTM Zero tank overfill protection systems are the benchmark in pressureless fast fill systems.

The unique patent pending* design is energised by the flow of fuel, which means no external power source is required, no specialist skills are needed to install, and the system is cost-efficient when compared with other options.

(* Patent Pending PCT/AU2015/050802, AU2016903857)

FillSafe Brochure

Pressureless Overfill Protection Refuelling Solutions

Why go Pressureless?

Avoid fuel spills, sprays, and fires

Refuel at up to 1000lpm / 264gpm

Automatically detect when the tank is full, and cease refuelling

Protect your people, and avoid damage to valuable equipment

Avoid Fuel Spills, Sprays, and Fires with this affordable solution from Banlaw. Get a quote for your machines today.

Product Catalogue

Over 700 products designed for heavy industry and guaranteed to work

Benefits of the FillSafe Zero Tank Overfill Protection System:

No pressure build up in the tank

Prolongs equipment life and avoids tank splits and spills.

Superior flow characteristics

Unlike some competitor systems, Banlaw has designed FillSafe Zero as a single package (i.e. Dry Break refuelling and overfill prevention in one integrated solution). This means optimised fuel flow, and very low pressure-drop through the Flow Control Valve which ensures higher refuelling flowrates without premature nozzle shut-off.

Consistently accurate tank filling to your specified levels

The system automatically terminates fuel flow once the tank is full, so no overfilling of machines, and no break downs from accidental underfills.

Single Pilot Line

Only a single pilot (signal) line is required, with the option of routing the line either internally or externally to the tank(s).

Exceptional fill speed

200lpm (53gpm) all the way up to 1000lpm (264gpm).

Works with your existing refuelling hardware

Our Flow Control Valves with their integrated Dry Break Receivers have been configured to operate reliably with the widest possible range of Banlaw and other-brand Dry Break refuelling nozzles.

Less sprays, slips, and falls

Operators do not need to stop refuelling, check how full the tank is and continue. FillSafe Zero ends the refuelling event automatically. This reduces the instances of staff getting hurt when climbing on equipment, and dramatically speeds up the process.

Compatibility

Banlaw FillSafeTM Zero Flow Control Valves and Level Sensors can be used (interchanged) with a variety of competitor OFP products. Contact Banlaw or your nearest authorised Banlaw distributor for further information.

Simple installation

Fitting the 2” Flow Control Valve and Venting Level Sensor requires no hot-work or external modifications to tanks (easy retrofit).

Reliable

Incorporates both primary (pressure-less) and secondary (pressured backup) overfill protection to ensure tank filling is stopped automatically, every time. Operators can initiate a refuelling event, and then invest their time in other important maintenance tasks.

Suitable for most tanks

The range of product options in the FillSafe Zero family means almost all industrial machines and small to medium diesel storages can be fitted with this system.

Customise to your requirements

If your tank requires a non-standard ullage, or your deployment is of more complex design, contact the specialists at Banlaw to discuss a solution specific to your needs.

Get the Kit. Problem Solved!

Our FillSafe Zero products have been designed to mix-and-match; making them suitable for installation on Dozers, Graders, Haul Trucks, Plant Equipment, Stationary Tanks, Excavators, Locomotives and more. Click on the type of equipment which interests you below, to view an example installation and bill-of-materials.

FillSafe Brochure

Pressureless Overfill Protection Refuelling Solutions

Available Product Types

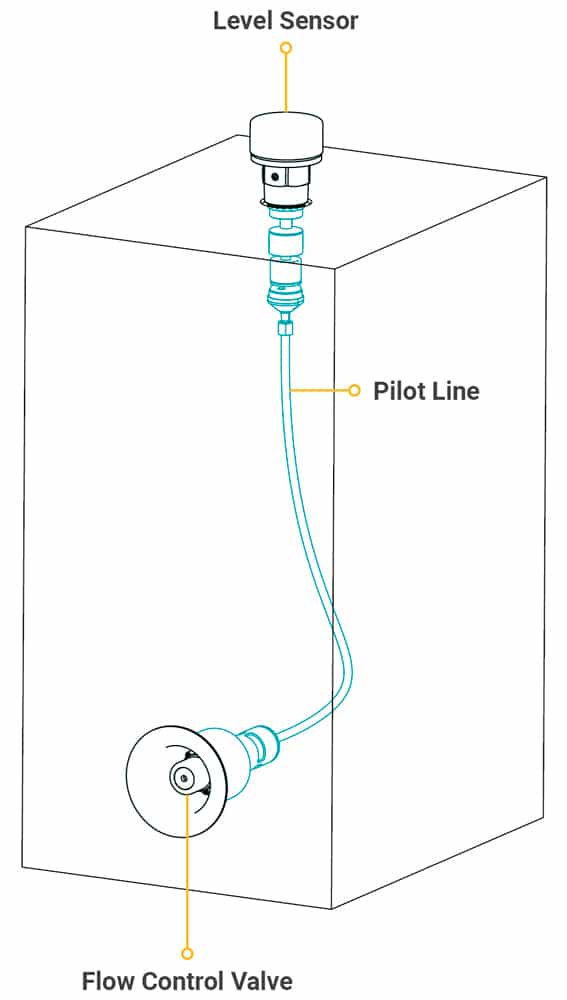

A Banlaw FillSafeTM Zero system consists of a Flow Control Valve, a Level Sensor, and a Pilot Line.

Click below to view our feature rich FillSafe Zero product range. We have cost-efficient solutions for an incredibly wide range of diesel-powered machines and stationary tanks.

Product Catalogue

Over 700 products designed for heavy industry and guaranteed to work

How The System Works

In a FillSafe Zero system, the Flow Control Valve closes when a Level Sensor detects that the tank is full, stopping the flow of diesel from entering the tank.

The FillSafe Zero architecture is highly flexible. Customers can mix-and-match the various Flow Control Valve and Level Sensor options to suit their specific requirements, including multiple tanks on the same machine, remote mounting, integrated tank venting, and cost minimisation.

"The Regulator’s position is that all fires on mobile plant are avoidable and preventable and the Regulator has adopted a zero-tolerance approach where mine operators have not taken appropriate steps to manage this risk."

NSW Resources Regulator - September 2021

Popular Content

Cat 992 Loader multi-tank refuelling

Following the success of the field trial, and subsequent multi-tank installations of FillSafe Zero, the solutions deployed for the Cowal Gold Mine have now been distilled into standardised and integrated Banlaw refuelling and overfill protection products.

Tank Overfill Prevention – Are your tanks spill free?

Are your generators, vehicles, plant equipment or stationary tanks overfilling? There are numerous ways to manage the risk of tank overfill, and in this blog article, we’ll lay out some of the most common, along with the pros and cons of each. Your first question is probably ‘Why should I...