Managing industrial fluids for the mining industry

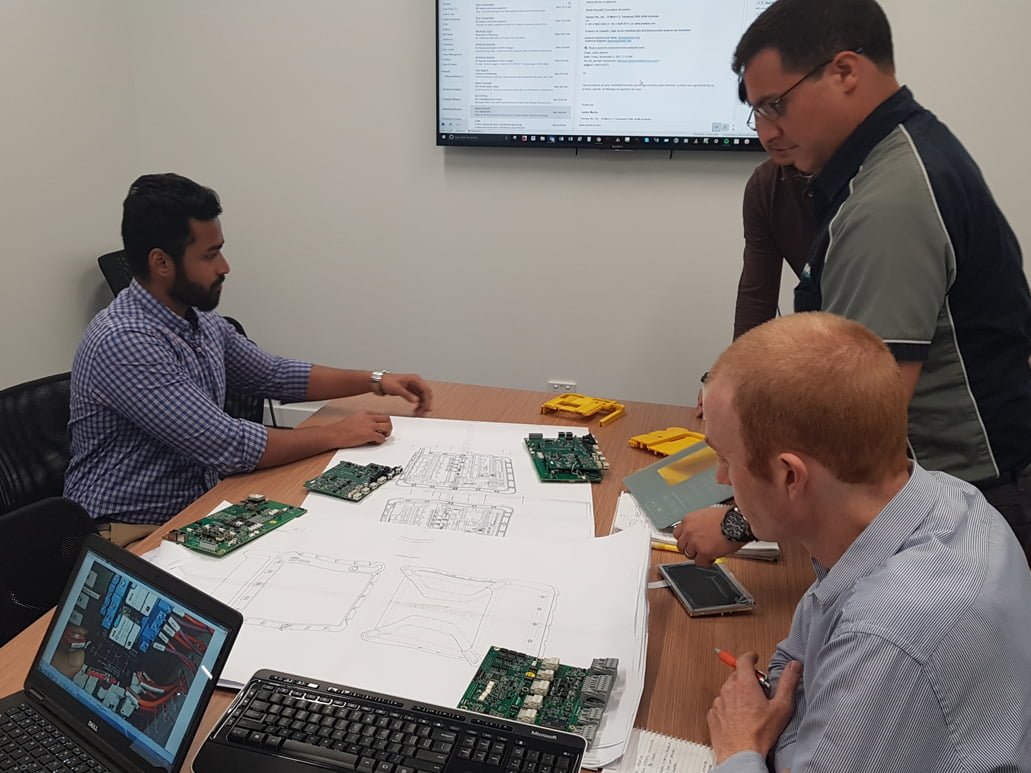

More often than not; the creation of innovative technologies does not come from ‘flashes of insight’. Innovation is a process that occurs when talented people with the right blend of skills define challenges, generate solutions, and then plan and execute together to produce something new.

New product development at Banlaw focuses around refuelling solutions, fluid transfer and fluid evacuation, pressureless refuelling, and fuel management. To keep moving forward, we commit to and invest in a roadmap for each of these product families. Perfect may not exist, but by working the plan, we keep punching away at technical barriers, delivering incremental improvements and brand-new capabilities.

(They may not wear capes, but these are the heroes in hydrocarbons)

Banlaw also invests in a core team of engineers. We can call upon specialists in machine and facilities maintenance, mechanical engineering, electrical engineering, software development, process automation or hazardous areas simply by walking as far as the coffee machine. Maintaining this core cross-functional skillset is at that heart of how Banlaw drives continuous improvement in hydrocarbons.

We have structured our innovation hub to ‘power-up’ our innovation processes. Just in the last year and a half, the Banlaw engineering group have released 185 new products, so we think the process is working!

When it comes to technologies that are right at the bleeding edge of R&D; we also partner with specialist vendors around the world, to get exposure to the latest research and methods.

Mining innovation – the important bit is what happens when things don’t go to plan

“No plans survive contact with the enemy” – Helmuth Von Moltke

We’d like to say a special thank you to all those Banlaw customers who have been willing to be first.

Once internal testing is complete, extensive field trials are a crucial part of bringing innovative technologies to the market. Failures during trials can have an immediate productivity impact so we always commit the right team, with a high priority focus to this part of the process. Mining companies trust us to try new things because we’ve been in fluid management for a very long time and we always have a backup plan to protect the customer operation. More often than not that backup plan includes Banlaw’s ‘old version’, the product that everybody else is still referring to as ‘best in class’! The customers who engage in field trials are then rewarded with new levels of performance before anybody else.

Banlaw teams show a ‘just make it happen’ attitude when new products are being tested in mine sites and railways:

- When we identified an issue writing vehicle configuration details to our field controllers (while trialling our new fuel management system), our electrical and software engineers threw everything at the problem. In the end they re-wrote and re-tested firmware and also remote software functionality, from scratch, in just four days

- It was similar with our new grease transfer coupling trials. Different operators intuitively use a quick disconnect product in slightly different ways, and different machine install scenarios generated new insights. Our engineers acted upon these learnings with rapid prototyping, and subsequent performance and usability improvements to the flat face coupling for grease.

Fluid management problems – Banlaw solutions

Making customer problems go away is the reason our engineering and service teams get out of bed in the morning (or during the night if we’re trialling on a 24/7 site!). Sometimes, it’s creating a shiny, new solution to an old problem, and other times it is about squeezing extra value out of what you’ve already got. Here are a few recent customer scenarios, where Banlaw took an innovative approach, and delivered excellent business results with our fuel management solutions.

Problem:

- Customer had an ageing IT estate, and the budget for new computing technology was still a couple of years away.

- Administering hydrocarbons on site was an extremely manual process. Each fuel dispensing location needed to be visited by a person to physically download transaction data. The data then needed to be taken back to the office, compiled from the various datasets, and manually analysed.

- There was a significant delay between problems occurring, and fixes being put in place.

- The site wanted to install FMS software, but it had to be compatible with their existing network.

Solution:

- We were able to quickly complete an investigation, quantify the risk, and identify servers which might be able to run the software.

- We tested in the ‘older IT environment’ and established that a Banlaw fuel management solution could be deployed.

- All fuelling and storage locations were connected to the FMS, as part of a networked and real-time information framework. The new solution was designed to enable efficient fluid management processes and provide the data the operation needed in real time.

- The customer now has fuel reconciliation insight ‘that comes to them’, rather than the other way around.

Problem:

- The customer had very limited fuel storage available onsite, and with production increasing, stock outs were a real concern.

- Taking dips from a 15-meter tank in the unloading area was a hassle for staff, who had to walk hundreds of metres just to establish whether a fuel order could be placed.

- When fuel tankers arrived, but were not able to make a complete delivery, it led to the customer paying for the same diesel to be delivered twice.

Solution:

- A cloud-hosted deployment of Banlaw ResTrack RMS, coupled with Banlaw’s unique real time automatic tank gauging means the team on site can now rely on the system to provide the information needed to run the business.

- Automated alerts provide stock re-order notifications to multiple recipients, eliminating the risk of stock outs.

- Tank levels can be checked anywhere, any time using a mobile device with a web browser, allowing fuel stores to be moved around and ensuring tankers can be completely unloaded each time they arrive.

Problem:

- A mining company required a solution for efficiently receiving, managing, and moving large quantities of diesel

- They also needed to control fluid degradation by utilising older stock first

- As with the previous example, it was also important to this customer site that when the B-Doubles and B-Triples arrived, the entire delivery could be received.

Solution:

- Banlaw fuel management solutions, and automated stock rotation (PLC/MCC) functionality ensure that there is room for all deliveries to be received, and that fuel stores are consumed on a first-in, first-out basis to mitigate degradation.

- It was identified that fuel delivery options had become much more reliable over the last couple of years, and receiving smaller deliveries every day represented the chance to free up significant OpEx

- Automatic notification processes advise local managers as well as the fuel vendor on how many semi-trailers of fuel will be required on any particular day.

- The risks of stock outs and unloading issues have been negated, by deploying a highly proactive and autonomous process.

- Over $5,000,000 has been made available for the operation to use, because it is no longer tied up as stored diesel on site!

Innovative technologies for the mining industry – well over 500 products, and more on the way

Fuel Management is not the only subject area where exciting things have been happening at Banlaw. We’ve just released our new Interactive Product Catalogue, and we’re pretty excited about it. We know that you wanted to be able to find products more quickly. Now you can:

- Search by keyword

- Search by part number

- Browse by category

- View photos of each product type

Inside our Interactive Product Catalogue, you’ll find:

- Arctic Range products spanning Diesel Refuelling, Fluid Transfer, and Overfill Protection categories

- The new Grease Transfer Coupling for faster, safer, and cleaner processes

- Our Venting Level Sensor for pressureless refuelling on a wide range of machines and diesel-powered equipment

- An in-line version of our 800 Series Flow Control Valve. It will enable tank overfill protection, and is compatible with pretty much any 2″ NPT input!

For a quick look at the new Grease Transfer Coupling (GTX) in action, this YouTube video outlines how to use it safely.

We urge you to contact a specialist at Banlaw to discuss innovative fluid management solutions to transform your safety and productivity today.

Click below for more details:

Quick Disconnect Grease Transfer Coupling

Pressureless Refuelling & Tank Safety