Understanding how your fleet is performing

Knowing where your money is going is the first step to being able to reduce your fleet management costs, which makes up a dramatically large proportion of your business expenses. Having an effective management strategy in place can be a daunting – and often overlooked – part of managing a fleet of vehicles, whether it is just a few to hundreds of wheels on the road. We have complied some helpful tips on how to understand and ultimately reduce your fleet management cost.

Have a clear register of your assets

It might seem obvious but starting from the start is the best way. Having clear documentation is essential to Understanding how your assets are being used. Have a list of all the vehicles that are to manage under this system. Make to also include vehicles that are currently out of rotation, in for maintenance or off the road for any other reason. Next to each asset, describe what they are used for. This will be the easiest way to check if each asset is being used effectively. Not every vehicle with need a full set of tools or other pieces of heavy equipment for each trip. Lighten the loads where you can save as much money on fuel as possible.

Proactive Maintenance

Having an effective maintenance schedule that is pre-emptive of issues arising will reduce downtime and ensure assets are not out of action when they are needed. Monitor the engine hours, tire pressure and other maintenance tasks. Regular servicing with a proactive approach will extend the life of your fleet and help reduce fuel costs, as well as ensure the safety of your drivers. Take note of vehicles that are needing a higher frequency of service – it may be time to sell that asset in favour of a better performing vehicle, for the benefit of the entire fleet.

Regular tire maintenance

Taking care of the tires on your vehicles can extend the life of the tires, boost your vehicle’s performance and help to cut down on fuel consumption. Low pressure or tires out of alignment can contribute to a higher fuel consumption. The tread should never be left if it is only just passable – consider the safety of your drivers, not just the bottom line, when checking the fleets tires.

Driver Behaviour

Paperwork and Refuelling

Your driver literally has your company in their hands. They are on the roads, using the fleet, to make your business work. However, they also need to be monitored to ensure an efficient workforce. GPS tracking provides real-time fleet visibility, and ensuring drivers are on time, taking the most effective routes, and not losing time to downtime, idling at petrol stations for excessive breaks. Also, reduce time consuming paperwork that is done manually. The documentation that needs to be done to monitor staff and their loads can all be done digitally, with most of the tasks being automated. One example of this is a fuel management system, which incorporates software into the refuelling system, to automatically track how much fuel is being transferred. This not only saves your drivers time and effort, but it also ensures accurate readings and limits the potential for human error.

Onboard Weight and Aerodynamics

Unnecessary cargo or heavy equipment can significantly impact the amount of fuel it takes to power your vehicle. Small gestures such as eliminating unnecessary tools can make significant savings when tracked over the life of a vehicles. Wind drag can also be reduced by keeping the windows rolled up, using covers over flat beds, installing aerodynamic side mirrors and eliminating unnecessary decorations such as flags.

Education

Having onboard GPS tracking will also show you the manner the vehicles are being used. Driving too fast will use excessive fuel, as will breaking too harshly repetitively. Consider investing in your fleet’s drivers through further driver education. Be a company that not only has – but enforces- a safe driving policy. Safer drivers are also less likely to be involved in incidents, which will save you on costly measures, like insurance, changing tires too frequently, asset down time, and even fuel.

Routing

Especially when a company has brought new vehicles into a fleet without changing the routes of the existing vehicles, it can be easy to forget that there is easy room for improvement in your fleet management by tracking individual routes and altering them. Drivers who may have needed to cross to the other side of the city may be able to swap their task with someone who is already heading that direction. Make sure to look across the entire fleet to maximise the efficiency of the fleet’s movements. Take notice of road closures, and new bypasses – the cities are growing and changing at a rapid pace, and there may be a faster route to take than the last time you checked. This will also help you save on maintenance (by driving on better quality roads), and fuel costs.

Automate your Fuel Management System

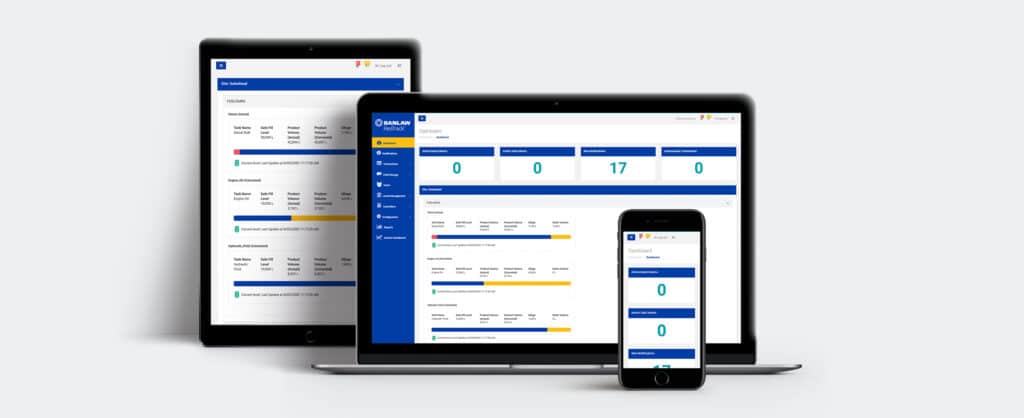

Using a professional service to manage your fuel and refuelling can make an enormous difference to your fuel usage and costs. Banlaw can automatically track the fuel usage of individual assets, and track across the entire fleet. They can easily instore software into each of your assets, provide the right refuelling hardware to ensure no loss of fuel, and monitor your drivers for speed, down time idling, and their own safety.

Banlaw can help you reduce your fleet fuel costs and give you an insight into your fleet vehicle operations so you can make educated management decisions. It will enable security, access, and control of fuel stores, whilst monitoring delivery and consumption.

Mark Fretwell

Mark is a mechanical engineer with over 11 years of experience in the hydrocarbon transfer industry. Currently, he works as a Mechanical Design Engineer for Banlaw, where he specialises in the implementation of Banlaw products and systems onto diesel-powered locomotives. Prior to his current role, Mark worked as a Sales Engineer, where he served as a Business Development Manager across NSW, VIC, TAS, and New Zealand. He worked directly with Banlaw’s distributor network and end customers, acting as a liaison between the Banlaw engineering team and customers on key R&D projects. He is always eager to share his knowledge and experience and is available for inquiries regarding diesel locomotive refueling systems, fuel management systems, or depot refueling infrastructure.