Situation

Your dry break refuelling equipment just isn’t really cutting it. Machines are running out of fuel unexpectedly, automatic diesel refuelling setups won’t work automatically anymore, and fuel is draining out of some tank vents after refuelling… Your team is wasting time and money trying to work around these issues, and some of these symptoms are really dangerous!

You’ve been tasked to find a solution quickly. Great news – a simple and affordable technology can permanently configure these problems out of your site refuelling processes. Presenting your ultimate problem-solving solution for high flow refuelling success: spring settings.

Let's break it down. What exactly is a 'spring setting'…?

Traditional pressured-shutoff dry break refuelling setups function optimally when three system components work in harmony:

- A tank breather vent in the top of the fuel tank allows air to rapidly escape as the equipment is refuelled. When the diesel in the tank reaches the correct level, the vent will close, allowing pressure in the fuel tank to increase momentarily.

- The connected diesel fuel nozzle will sense this hydraulic pressure pushing back against the piston, and when this force overcomes a precisely calibrated spring within the nozzle, the fluid path will close, and the nozzle will automatically lock itself into the ‘Off’ position.

- The fuel receiver at the tank fill point is always seeking to return to the closed position (ensuring that fluid stays inside the tank). A precisely calibrated spring within the receiver works in tandem with the one inside the fuel nozzle, optimising shutoff behaviour for the machine being refuelled.

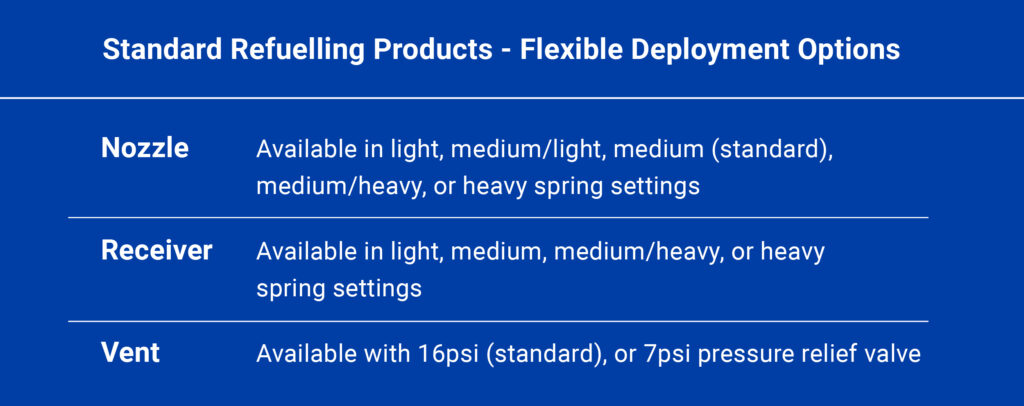

Uniquely Banlaw: Unlike other dry break fuel system manufacturers, we don’t believe in one size fits all. As soon as you have multiple refuelling locations, service carts, or a fleet comprising different machine types / OEMs / tank architectures, then small variations between one use case and the next will make themselves known via refuelling problems. Our solution is to supply diesel fuel nozzles, receivers, and tank vents in a range of preconfigured settings. Need to optimise the dry break fuel system setup on a machine? Change the receiver. Need to adjust the setup for all machines that use your refuelling bay? Then it’s time to perform due diligence related to flow rates, refuelling setups, etc. (a different nozzle spring setting could be part of the solution).

With Banlaw refuelling products, the root cause of dry break fuel system issues can be simply and permanently overcome. Whilst a medium spring setting is perfect in most situations, just choosing a different receiver for the fuel tank may overcome the majority of persistent fuelling challenges. If you are having refuelling issues on your worksite, please speak with a Banlaw specialist. We’ll help you look at your system and flow rate requirements to identify the most suitable way to alleviate the issue.

Overfill Prevention Brochure

FillSafe pressureless tank filling products to avoid overfills and underfills, guaranteeing that tanks are filled to the optimum ullage every time.

Banlaw Product Catalogue

Cleaner, safer, and more efficient fluid transfer and evacuation products

Let's solve the common refuelling problems

with spring settings:

Problem #1 – PREMATURE SHUTOFF

“Our refuelling equipment always seems to be working against us, we’ve got wheel loaders where the fuel nozzles just keep turning off too early, and we have to hold the nozzle ON to completely fill the tank.”

Solution

Firstly… never hold an Auto Shutoff Fuel Nozzle into the ‘On’ position. It is extremely dangerous, and you have overridden the auto shutoff feature by doing so, dramatically increasing the chances of spills, sprays, and equipment fires. It it really important to fix the root cause instead.

The reason these machines are causing the fuel nozzle to shut off early is likely to do with there being more components or complexity in the refuelling system or tank architecture. Additional back pressure could be coming from elbows, flow control valves, a significant elevation of the tank above the receiver location, long refuelling pipework, etc. The solution is probably to use a Light receiver on those machines, but please give us a call so we can help you troubleshoot the issue.

(Holding or tethering fuel nozzles into the ‘On’ position is a leading cause of tank overfill. Fix the root cause instead)

Problem #2 - OVERFILLS

“We’ve got diesel coming out the tank vents when we refuel our drill rigs, and we’re worried about someone getting hurt.”

Solution

Tank overfills are really dangerous. They are also completely avoidable, so these days most regulators have no patience for them whatsoever. Tank overfills cause spills / leaks / sprays and are a leading risk of mobile equipment fires. Frequently overfilling a fuel tank exposes it to pressures far and away beyond what it’s designed for each time the fuel hits the top of the tank. Even if it only appears minor, frequent overfilling is likely to degrade the tank, potentially even splitting it.

To assist the fuel nozzle to turn off a little earlier, and therefore reduce the amount of pressure inside the tank when the system is triggered to close, we often recommend a different receiver on machines that are prone to overfill. As usual, we encourage you to speak with us and troubleshoot the situation first to ensure we’ve identified the correct root cause. Tank overfills are particularly dangerous, so selecting the appropriate receiver or other components is critical.

(Tanks and pipework on mobile equipment damaged due to non-functional overfill protection systems)

Problem #3 - PRODUCTIVITY

“Our reporting shows we are losing valuable work time because our in-pit refuelling area takes much, much longer to fill machines, and the vehicles also come back to refuel more often than normal. We think they’re being under-filled.”

Solution

When recommending different fuel nozzle spring settings on a site, we always do a risk assessment first. Making an inappropriate change to the infrastructure-side refuelling setup will affect every piece of equipment that gets refuelled there. There is the potential to overfill many machines, so we need to scope this situation properly before providing an answer.

The answer could be a different refuelling nozzle spring setting although this is usually the last resort. Most issues relate to the plant equipment being filled.

In terms of contributing to site productivity, this is a really interesting question. We’d first consider what your site business standards are for fluid transfer and access. What filling methods and flow rates are all the machines using that location specified for? What are the average refuelling durations and flow rates? Is significant manual process time part of the situation? Are vehicle queues contributing to the problem? Is it only an issue during certain parts of the day?

Here are just a few ways we help our clients drive site productivity through improved processes related to the refuelling event:

- Resolving any machine-side or infrastructure-side refuelling hardware idiosyncrasies to ensure assets are being efficiently filled to the optimum ullage (maybe it’s a nozzle, maybe it’s a pump, or maybe you just need a tank overfill protection system)

- Migrating machines to a higher-flow process (Splash Fill might be 40lpm to 80lpm (21gpm), whereas Dry Break processes tend to be 300lpm all the way to 1000lpm (264gpm) depending on your specific infrastructure and machine configurations)

- Automated fluid access and data capture technologies can speed things up by a couple of minutes per machine every time an asset is refuelled (no manual authorisation or paperwork)

- Installing an extra dispensing setup, so additional vehicles can use fuelling infrastructure at the same time multiplies productivity

- Leveraging a service cart / fuel truck to supplement the refuelling area at peak times can mitigate productivity issues without having to install anything new at all

- Scheduling and synchronising shift changes with refuelling events means the machine idle time related to both subjects occurs simultaneously. Staggered shift changes can also de-burden fuelling infrastructure that’s already at peak utilisation

(Significant site productivity gains can be realised by optimising the refuelling event)

Banlaw refuelling processes and technologies are standardised for superior reliability and performance. We also understand that no two operations are exactly the same, and so we create features like having a range of spring settings in our dry break fuel systems.

Choosing Banlaw diesel dry break fuel nozzles, receivers, and vents gives you the ability to ‘massage problems out of the system’. Additionally, your site achieves heightened performance from equipment that keeps going and going and going.

Here at Banlaw, we want your refuelling equipment to work with you, not against you. The highly configurable nature of Banlaw’s refuelling solutions offers you a unique problem-solving tool for increasing your site safety and performance. Take the guesswork out of resolving diesel refuelling issues – speak with a specialist at Banlaw today!

Overfill Prevention Brochure

FillSafe pressureless tank filling products to avoid overfills and underfills, guaranteeing that tanks are filled to the optimum ullage every time.

Banlaw Product Catalogue

Cleaner, safer, and more efficient fluid transfer and evacuation products

Contact Banlaw for outstanding environmental, safety, and productivity outcomes. We’re the Dry Break Refuelling experts.

Popular Content

3 strategies for reducing carbon emissions whilst boosting your business outcomes

The Paris agreement saw 195 nations taking a collective pledge to proactively combat climate change. This commitment to reduce emissions has resulted in significant reforms and compliance requirements across many vital industries.

Dry Break Fuel Coupling – Break Away Valves

Banlaw’s Break Away Valves are designed to fracture when a specific amount of lateral stress is applied. This means that should a vehicle drive-away during refuelling, the valve assembly will separate into two Dry Break components. This minimises spills, avoids fires, and stops expensive refuelling and fuel management hardware being...

Diesel Tank Vents

Banlaw has a range of robust diesel tank vents built from high-grade materials for strength and durability to suit any operating conditions. Our diesel tank vent system provides overfill protection by determining the refuelling system’s shut off level. The vent mechanism seals the fuel tank when it is full, and...

Refuelling

We design, engineer and manufacture a range of high performance diesel refuelling components including dry break nozzles, dry break receivers, vents and dust caps. Our products are designed and built for reliability and performance, and used in some of the harshest work environments around the world. Our Dry Break Nozzles...