What is Talk Overfill, and why is it important to avoid? Tank Overfills or errors during refilling processes can cause economic, equipment damage and environmental issues. Having effective Tank Overfill Protection on your site can prevent facility and mobile equipment damage, including fires. This critical technology can mitigate safety risks and contribute to your company’s productivity.

What is Tank Overfill?

Tank overfill is the term used when a product inside a tank rises to a critically high level. It can cause spills, sprays, and tank damage, which is messy, costly, and dangerous to your workers as well as your bulk fuel installations and mobile equipment. Overfills are a common yet completely avoidable cause of operator risk and fluid pollution. Tank Overfill Protection Systems help construction, mining, agriculture, fleet, and railway operations that need to fill storage tanks and refuel diesel-powered machines reliably. A well-designed and maintained solution can dramatically reduce your company’s unplanned expenses.

What Happens When Tank Overfill Protection Systems Fail?

When there are ineffective fuel management systems or mobile-equipment tank overfill protection solutions in place, the result can be worse than just lost income. It goes beyond any environmental concerns, to the safety of your people, your employees, your friends.

Overfilling a diesel tank can create internal pressure, leading to flammable liquids, sprays, or vapours being released and potentially igniting. This is essentially what happened during the now-infamous 2005 BP Texas City Refinery explosion. A large hydrocarbon storage tank spilled due to ineffective automatic tank gauging and tank overfill protection systems.

The spill was ignited by a vehicle operating on site. The resulting explosion tragically killed 15 workers, injured 180 others and severely damaged the facility. On top of the appalling human cost, the refinery was also slapped with over USD 50 million in fines.

The most cost-efficient and straightforward way to avoid this kind of disastrous but completely avoidable situation is to install and maintain an appropriate Tank Overfill Protection System. Banlaw can provide the optimal solution for safe and efficient filling of your storage tanks. We deploy bulk storage overfill protection systems as part of our fuel management system projects for diesel tanks and tank farms. We also manufacture both electronic and mechanical tank overfill protection systems for mobile equipment and plant.

What is the Importance of Tank Overfill Protection?

Safety is always the number 1 consideration, safety for people as well as expensive equipment assets. Then there are environmental considerations and the cost burden of unplanned equipment downtime and maintenance. All of these risks are significantly reduced by installing and maintaining appropriate tank overfill prevention technologies. An effective tank overfill protection system can significantly increase the efficiency of liquid refilling, saving valuable time with every fill and increasing the productivity of your fleet or built infrastructure.

Standards Regarding Tank Overfilling

International compliance standards are stringently enforced to prevent disasters like the one outlined earlier in this article. It has been legislated that operations have a “responsibility to ensure compliance that the equipment is designed, maintained, inspected, tested, and operated in a safe manner”; this includes preventing overfills, and ensuring that proper fluid levels for liquids are maintained within tanks. Installing and maintaining an overfill protection solution provides compliance, safety, and financial benefits.

What are the Benefits of Banlaw’s Overfill Protection Systems?

Banlaw Tank Overfill Protection Systems allow for diesel storage tanks, fuel farms, heavy equipment and other fluid storage vessels to be protected whilst also improving process efficiency. Key benefits include:

- Safety compliance for your bulk fuel installations

- More efficient diesel refuelling for mobile equipment

- Minimisation is leaks and spills, avoiding environmental situations, as well as the attention of resource regulators

- Secondary backup overfill prevention features with Banlaw FillSafeTM solutions, a second layer of protection as standard!

- No pressure build-up in tanks, avoiding metal fatigue and tank rupture

- Reliable tank filling every time. Tanks are filled to the optimum ullage every time, not overfilled, and not underfilled

What types of Overfill Prevention solutions does Banlaw offer?

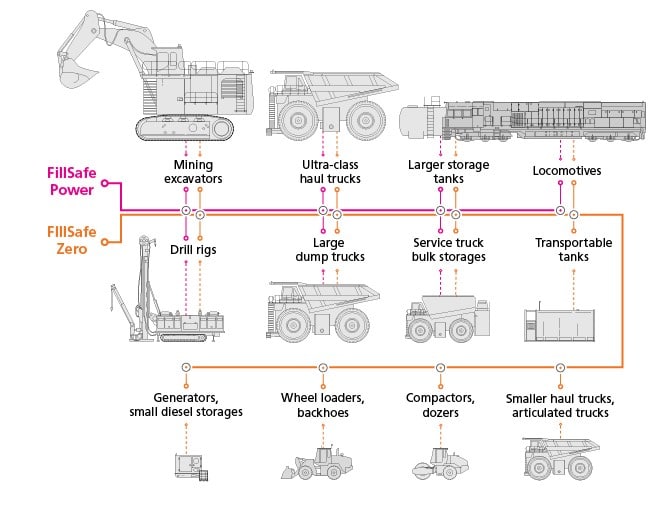

Banlaw’s tank overfill protection offerings fall into three categories. FlowLogix is our project-based built infrastructure. Our engineers design a tank overfill protection solution to your specific scope as part of an overall fuel tank farm piping design. FillSafe Power is our premium electronic solution for all kinds of liquids and is perfect when maximised flow rates and safety are required. FillSafe Zero is our highly-affordable mechanical solution for diesel-powered machines.

FlowLogix

Banlaw FlowLogix™ delivers bulk storage tank overfill protection and process automation as part of a custom-engineered infrastructure project. This may include leak detection, pressure-change alarms, fluid level alarms, and SIL-rated, compliant bulk storage overfill protection systems. Our specialists in fuel management systems, hazardous areas, diesel storage tanks, and tank farm piping design create the perfect solution for your operation.

FillSafe Power

FillSafe Power is our electronic tank overfill prevention system for critical machines and stationary tanks. It is a compact, off-the-shelf product and totally unrestricted by flow rate or liquid type. FillSafe Power works due to a float valve inside the tank being triggered when the full-tank level is reached, causing a ball valve to be closed. Key benefits of FillSafe Power:

- Advanced electronics ensure the ball valve is always left in the closed position when tank filling is not underway, providing an additional physical control to avoid unplanned filling or emptying of the tank

- LEDs provide immediate operator feedback. There is no guessing. It is obvious when a tank is full, or requires filling

- Selecting the appropriate pipework and ball valve enables any type of fluid or flow rate to be supported

- Additional safety features, such as fire-safe valves can be readily integrated into the solution

- Service Trucks and other multi-tank scenarios benefit from the simplicity of installing a bank of FillSafe Power Controllers to control the filling of all tanks from one centralised location

FillSafe Zero

FillSafe Zero is our mechanical tank overfill protection system for diesel tanks. It’s hydraulically activated, and system components are installed at the diesel tank’s fill point or fuel supply line and the top of the tank. When the fuel inside the tank reaches the optimum level, the Level Sensor in the top of the tank triggers the Flow Control Valve (at the tank inlet) to close. This in turn causes the diesel fuel nozzle to turn off. Key benefits of FillSafe Zero:

- Highly affordable – it can cost less than a tank of diesel for some machines

- Like all Banlaw overfill protection products, it ensures zero pressure build-up in the tank

- Kits can be fitted to most diesel tanks in about 30 minutes, and no specialist skills are required

- Refuelling is simple and straightforward. The operator simply follows the normal filling process. There are no new processes to learn

- FillSafe Zero features superior flow path engineering and operability. Industry-best fuelling efficiency can be achieved because maximum flow rates are maintained until the tank is full.

- FillSafe Zero solutions are compatible with Banlaw, as well as other brand quick fill diesel refuelling hardware, simplifying site upgrades

Banlaw has been trusted to prevent tank overfill in heavy industries for over 40 years. Custom-designed overfill prevention solutions for fuel farms, maintenance facilities, and transportable bulk fluid storage tanks are created to your specific scope by Banlaw engineers and fabricators. Standardised products such as our FillSafe offerings are available via talented Banlaw distributors all over the world. Contact Banlaw today if you need cleaner, faster, safer refuelling and tank management solutions.

Think Fuel. Think Banlaw.